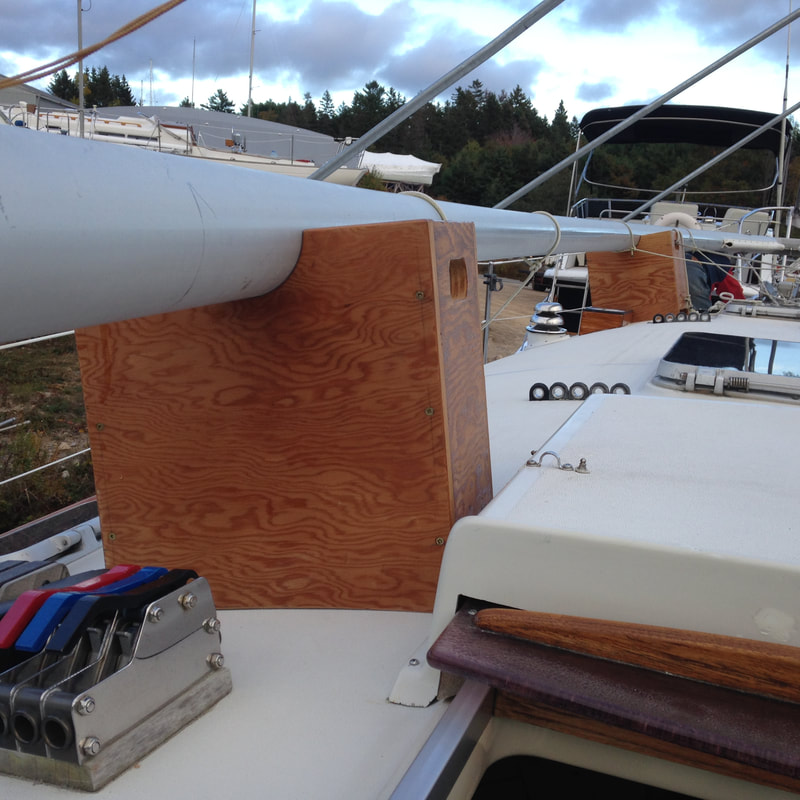

Chris, a talented wood worker, noticed that the previous owners of our boat had fashioned supports by nailing together short lengths of two x fours and thought it a bit rough. Without help, they were also difficult to work with when tying each block down and consequently, there was too much cross tying and lines involved, creating even more of a rat’s nest to work around.

So Chris designed while Gregg commented from the peanut gallery and a plan was formulated. They used ¾”plywood. After determining the height and width needed for the box, they cut a piece of plywood double the length and then cut a circle 4 ½” diameter (size of the wishbone tubing) out of the middle. Then they cut the wood in half creating two half-moon notches that would cradle the wishbone and form the forward and aft sides of the box. This was a clever way to make the half-moon cuts equal.

The diagram provided is not to scale, so follow the measurements not the picture. They left the bottom of the boxes open for drainage when the boat cover is off. Possible refinements include carpet strips along the bottom to help it conform to the radius of the cabin top but if not, these bottom edges can be scribed to fit the shape of the curve. It’s important to seal these edges of the box that sit on the gelcoat as moisture, in the plywood, will cause mold to grow during winter storage.

For the following haul-out, Chris had painted his and we varnished ours with leftover Epiphane from all the teak refinishing we did. Now I found it so much easier to work around the cabin top with the new boom-box storage system and fewer tie down lines. It also elevated the spar higher above the cockpit easing access plus the added bonus of less head bumping for those vertically challenged.

Chris & Tina Ouellette

Felina

NS30U, #261

Gregg & Christine Little

Catalyst II

NS33, #22

RSS Feed

RSS Feed