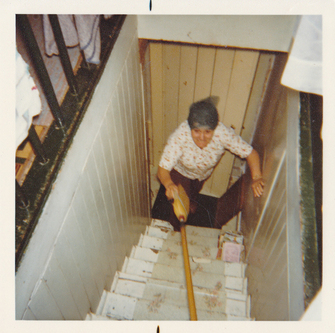

This is what you call heads above the rest....I couldn't resist!

This is what you call heads above the rest....I couldn't resist! Give him a job and he will come up with a way to make it easier and faster....things I've never even considered. I’m impressed that the apple didn’t fall too far from the tree and proud that he can beat his momma on a few things.

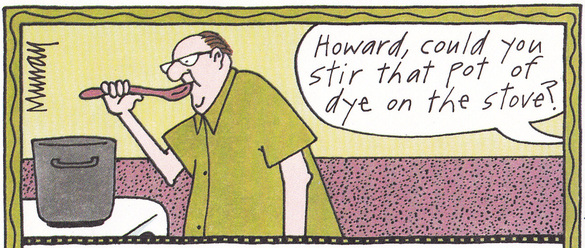

Shane does the dyeing for the shop, draws patterns and does arm-long lists of jobs that might not be seen on the surface but keeps the place running like a well-greased wheel. Everything he’s touched has been altered to work faster. I heard a saying once “Give a job to a lazy person and he'll find a way to do it faster”. Now Shane isn't lazy so that really doesn’t apply, but it could read, “Give a job to a genius and he’ll find a way to revolutionize the process.”

Different dyeing techniques call for various timing for prep and execution. Scrunching wool in a pan to spot can be labour intensive because the secret to the overall appeal is the tightness and height of the folds which of course, takes time to place. Then the uniformity of the various colours can depend on how you place the dye over these folds. Too high or floppy folds mean dye won’t seep to the bottom and you have to spend more time digging out between the flaps to find the white spots. My son has the spot dye down to a science. I'll admit his scrunching is superior to mine.…momma doesn’t have as much patience, so there’s more chance of being sloppy…the dear boy's words, not mine.

Spot dyes require proper pans and we’ve looked for them in yard sales and hardware stores. We've tried glass, enamel and steel all with varying results. I guess that would make Shane and I just a bunch of pan handlers..... Most large open-faced pans come with areas around the perimeter that are lower than the center of the pan, a trough along the edge for drainage when cooking I guess. After my father passed away I found two large pans in his panty that have served us very well over the years but I have never seen another pan like them so we pray they have a long life.

These stainless steel vessels hold a half yard of wool comfortably and although they still have that channel around the outer perimeter I have found it can be useful to create a slightly darker edge that can be used for a bit of shading. so if you have a grassy green spot and need a bit of a shadow under a bush, the darker edges are perfect!

Most of the enameled or glass pans we found weren’t quite the right size; the glass was too elongated and the enameled one was overall too small to make the right kind of folds needed to support all the different colours in the spot. So we toyed with the idea to have a few pans custom made and as we worked out the pros and cons the idea struck to have one fabricated large enough to hold an entire yard of wool and flat bottomed for even distribution of dye.

So we contacted a local welder and requested a pan with the dimension of the inside of our oven. As big as we could go without touching the inside walls of the stove. It worked like a charm. Of course everything had to be doubled, the formula and the water to sufficiently cover twice as much wool. We don’t use it often, Shane says that it takes him more time scrunching the wool into the tiny folds in the larger pan than he is able to process in two ½ yds ones, but I beg to differ and there might have to be a spot "dye off" to see which one leads the race. Even though it may take more time preparing the wool for the big pan, it does cut down on the energy spent in oven heat and that kind of efficiency saves money and, more importantly, dyes twice as much for the wool racks.

So for all you dyers out there that sell wool, having a pan made to order can cut down on the time you are slaving over a the spot dye. The pan cost $30.00 to have made and that was paid for with the first piece of wool dyed. One thing we didn’t take into account was that the two older stoves we work on might not have the same dimensions inside the oven so the pan we had made only fits the one stove. Who’d of thunk? Even genius can learn from experience! We had a second pan made and now we're covered.

One thing I will caution about. Make sure the pan's inside corners are smooth. No areas where dye can settle in and later ooze out to stain the next piece of wool. Explain to the person making up the pan that there can't be any areas that leave gaps or where dyed water can get in.

http://www.encompassingdesigns.com/dyed-spots.html

RSS Feed

RSS Feed