On Catalyst II, the exterior moulding of the instrument panel had been broken sometime before we bought the boat, so this was the perfect time to rebuild the edge. Gregg used epoxy and fairing compound to rebuild the corner using a masking tape dam so it would cure flat and have little sanding. Then he painted it black. (Fig. 1) The acrylic transparent cover was crazed to the point that you couldn’t read some of the instruments and later I found a replacement on the internet with the proper configuration we needed for the glow plug and starter button on our boat.

The first job was to cut the hole in the cockpit combing with a jig saw. Gregg used a rasp to clean off any rough fiberglass on the backside of the combing where the new recess frame edge would be glued to the inside. They took measurements of the openings on each boat then got to work building a thin plywood frame. (Fig. 2) On our boat there were two openings, one for the instruments and the other for an external speaker. They used Fiberglass and fairing compound to strengthen the plywood and then used more fairing compound and epoxy to smooth the corners and edges.

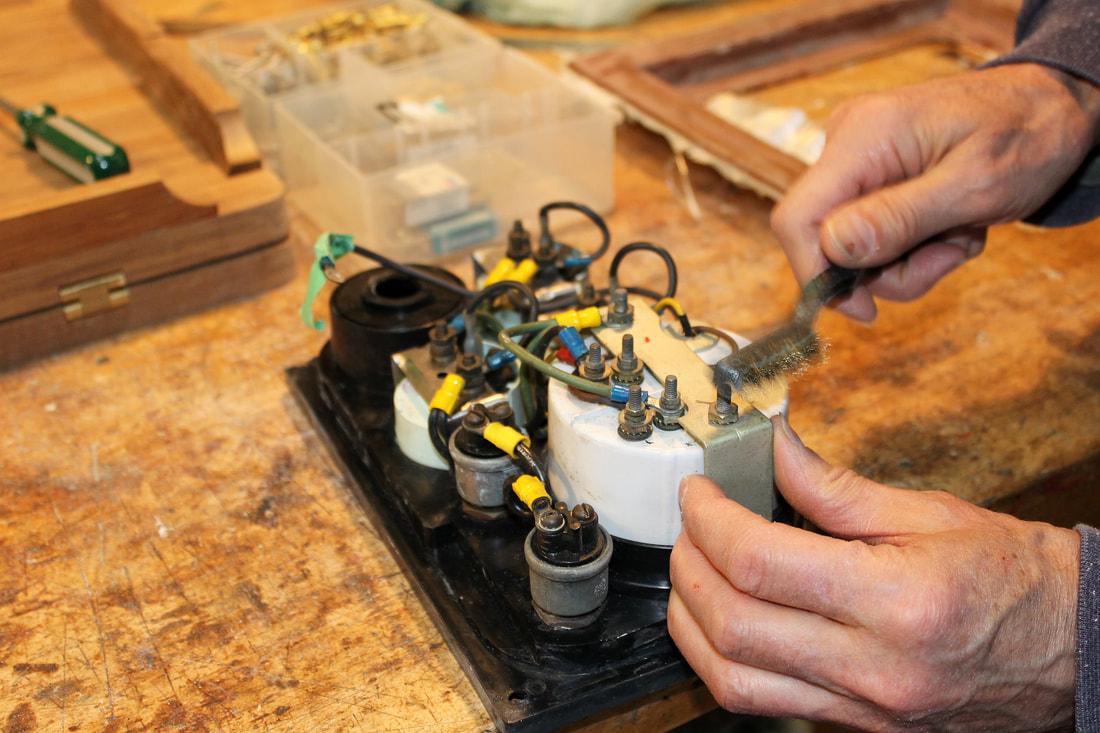

While waiting for the frame to cure, they both cleaned up all electrical contacts with a wire brush. An important tip, when they removed the instrument panel, all of the wires were labeled for easy reconnection. (Fig. 3)

When the new frame was cured, they trimmed the excess fiberglass around the holes and tested the fit with the instrument panels. (Fig. 4 & 5) They took the boxes to the boat for a dry fit. Take note of the lower right-hand corner on (Fig. 5) showing the broken moulding that was subsequently repaired.

Next, they applied epoxy to glue the recessed frame in place. The three screws held it while the epoxy set and then they were removed and fairing compound filled the holes. (Fig. 6, 7, & 8)

Fairing compound was added to produce a flush surface for both frames and then the following day they were sanded smooth. There was a lot of sanding involved to remove all of the blemishes to make it flawless and ready for painting. It really helps to have an onboard vacuum! (Fig. 9, 10 & 11)

Felina 30’s new recessed panel after painting and installation. (Fig. 12) The finished housing on Catalyst II before the instruments and speaker were added (Fig. 13) and then installed and working. (Fig. 14) Great job guys!

Christine Little

Catalyst 33, #22

Nova Scotia Nonsuch Group Secretary

Nonsuch Musings Facebook Page: https://www.facebook.com/nonsuchsailing/

RSS Feed

RSS Feed